|

|

|

France - country information |

|

Veliky Novgorod - Russia |

|

Riga - Latvia |

|

Helsinki - Finland |

|

Nha Trang: the weather has normalized, but the infrastructure has not been restored yet |

LATEST REVIEWS

LATEST REVIEWS

|

Choosing a portable toilet |

|

Plumbing faucets, the best of the best |

|

Green crops |

|

Dishwasher – freestanding, built-in or compact? |

|

How to choose a dishwasher - what you need to know |

Countries and cities

Countries and cities Engineering plumbing/Useful articles and analytics

Engineering plumbing/Useful articles and analytics Reinforced plastic, pipes and fittings

Reinforced plastic, pipes and fittings Reinforced plastic, pipes and fittings

For a long time, metal-plastic pipes have been used in plumbing. Let's find out in more detail what a metatloplastic pipe and fittings for it are

A metal-plastic pipe, this is an aluminum pipe insulated inside and outside with plastic, the inner layer of the pipe consists of plastic (plastic can be food grade, for drinking water supply and the usual cheaper for technical water supply), the middle layer is made of aluminum welded with a laser or ultrasound, the outer layer is again plastic (its function is to strengthen and protect the pipe from mechanical stress)

All layers are glued together with a special glue (therefore, the pipe can still be called five-layer). The technical characteristics of a metal-plastic pipe depend directly on the manufacturer for the average indicators, see below.

The main characteristics of metal-plastic:

- Withstand pressures up to 25 bar - at temperatures up to 20 ° С

- Withstand pressure up to 10 bar - at temperatures up to 95 ° C

- Outside pipe diameter from 16 - 63 mm

- Pipe wall thickness from 2 to 3.5 mm

- With proper use, the product can last up to 50 years

- Versatility of use (pipes can be used for floor heating, cooling, heating, plumbing)

- The main methods of connecting pipes - ("crimping" - tightening with a wrench and "pressing" - using a special electric press)

- Gas tightness

- Low thermal conductivity of the pipe

- Temperature range of use from -35 С to + 95 С

- Resistant to corrosion and chemicals

- Abrasion resistant

- Eliminates wall deposits

- Small roughness

- Low coefficient of hydraulic resistance

- Suitable for use in drinking water supply

- Sound absorbing ability

For ease of installation, all metal-plastic pipes every meter have a marking on the surface, which indicates the footage, operating conditions, manufacturer and more. Thus, you can use the marks to accurately cut the pipe into the required lengths. If necessary, after installing the pipes, the markings can be washed off.

For connections and transitions of metal-plastic pipes, special fittings are used. The range of offered types of connections and transitions is sufficient for the installation of any structures. The two most common types are crimp and press fittings.

Compression fittings are a body with a stem designed for the required pipe diameter, a nut is screwed onto the pipe, inside which there is a compression ring, the ring ensures pipe retention and tightness of the connection.

Compression fittings are used to connect pipes manually, installation does not require an expensive tool, after a year of use of the pipeline, it is desirable to pull the connections, since there is a possibility of weakening of the connections from temperature fluctuations. In this connection, it is advisable to locate the connections in accessible places, or to provide for special inspection hatches.

"Press connectors" have a body with a fitting on which a pipe with a pre-dressed metal sleeve is put on, the sleeve is crimped using a portable press, which ensures high reliability of the connection and the possibility of placing pipes and their connections in hidden places of the wall or under the tiles.

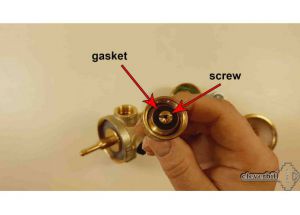

All fittings use a special dielectric gasket, which ensures that there is no contact between the aluminum part of the pipe and the brass part of the fitting, which makes the assembled plumbing system electrically neutral.

All fittings use a special dielectric gasket, which ensures that there is no contact between the aluminum part of the pipe and the brass part of the fitting, which makes the assembled plumbing system electrically neutral.

Reinforced-plastic pipes are widely used by both professionals and amateurs, they allow to provide the possibility of connection and installation of various levels of complexity.

|

|

| © tour-planet.com 2017 - 2025 |

Copying of texts, photos and other information for re-publication on other resources is allowed only with the written permission of the site administration. |