|

|

|

France - country information |

|

Veliky Novgorod - Russia |

|

Riga - Latvia |

|

Helsinki - Finland |

|

Nha Trang: the weather has normalized, but the infrastructure has not been restored yet |

LATEST REVIEWS

LATEST REVIEWS

|

Choosing a portable toilet |

|

Plumbing faucets, the best of the best |

|

Green crops |

|

Dishwasher – freestanding, built-in or compact? |

|

How to choose a dishwasher - what you need to know |

Countries and cities

Countries and cities Engineering plumbing/Useful articles and analytics

Engineering plumbing/Useful articles and analytics Leakage protection - Aquastop valve - helps to cope with a leak or not?

Leakage protection - Aquastop valve - helps to cope with a leak or not? Leakage protection - Aquastop valve - helps to cope with a leak or not?

We are testing the Aquastop leakage protection valve in real conditions. Simulation of partial leakage and complete breakage of a hose with a valve installed in the system.

I welcome everyone, in anticipation of the release of my article on leakage protection systems used in washing machines and dishwashers, I decided to conduct a small test of the Aquastop valve, which is widely recommended as a leakage protection, which can be used by installing it in various places of household water supply, for example, in front of faucets or inlet hoses of washing machines. or dishwashers.

You can watch a video about leakage protection options used by manufacturers of washing machines and dishwashers in my other video, the link to which will be in the description or attached commentary to this video.

So, the leakage protection valve is commonly referred to as Aquastop. The device is a housing inside which a spring-loaded valve is installed open and allowing water to pass through in its normal state.

Manufacturers recommend installing the valve in systems with a working pressure of 2 to 10 atmospheres, corrected for a standard pressure of 4 to 6 atmospheres. The actuation of the valve is stated within the water flow rate through the valve of 12 liters per minute.

The valve is triggered with a sharp increase in the flow of water after itself, which implies a situation with a break in the hose, an increased flow of water putting pressure on the spring and the valve, which does not have time to pass a large volume of water through its holes, compresses the spring and the valve completely blocks the passage of water.

I decided to test my valve at a water pressure of 2.5 bar, since my pumping station is adjusted this way, and the pressure in the central water supply of apartment buildings can often not reach a value of 4 - 6 bar.

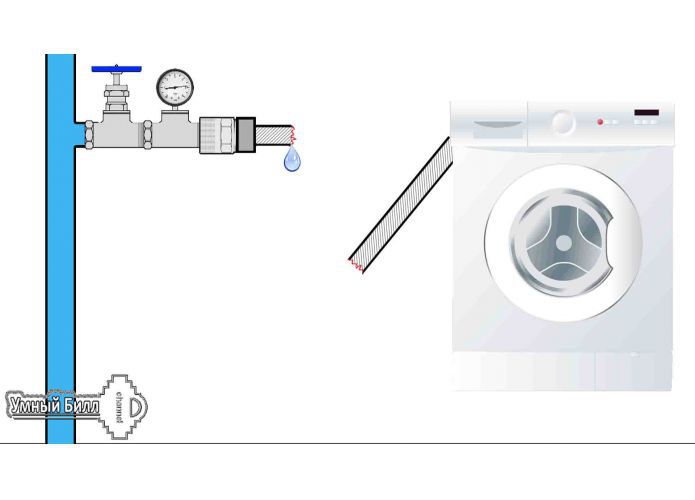

Having installed the valve in an impromptu stand, which is a garden hose with a valve at the end, I supply water under pressure to the hose, smoothly opening the valve at the end of the hose, it becomes clear that there is water in the system.

Further, I try to smoothly unscrew the valve to the end, thereby opening the maximum passage for water, at the maximum open valve the valve is triggered.

To return the valve to working condition, disconnect it from the system, then reconnect it in place.

Now, in order to create the situation of a torn hose as close as possible, I will simply try to cut it with a knife.

First, I make a small incision, we see that water is pouring through the cut, and the valve does not block the flow. Although a situation of this type is quite typical, for example, when a hose is damaged or when a cap nut is broken on a flexible hose with a metal braid, very often the water flows in a small stream, and provided that this can last long enough, a lot of water will accumulate in the room.

It should be clear to everyone that the valve is not capable of operating with such a leak, otherwise it would simply shut off the flow while the washing machine is drawing water.

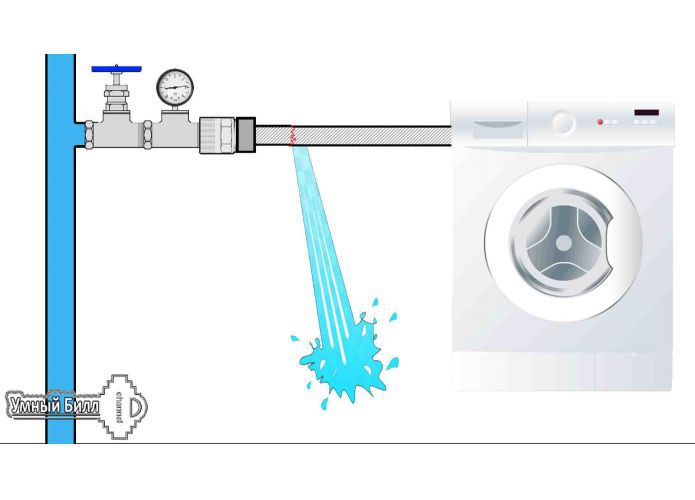

Then I will try to enlarge the cut, you can see that the water does not stop pouring further. And only after cutting the pipe completely, the valve is triggered.

What conclusions can be drawn from this. Such a Valve is only able to protect against leaks with a completely burst hose, and for normal operation it requires compliance with certain conditions - proper water pressure and flow rate through it, the higher these indicators, the higher the chances of the device being triggered.

The fact that the valve does not protect against partial destruction of the hose is most likely a fact, water can flow through a small damage for days on end and this will not be reflected on the valve, I repeat, otherwise it would have triggered to fill the washing machine tank or turn on the dishwasher.

Also, such a valve is characterized by, so to speak, "false" alarms, for example, if the washing machine has a fence of more than 12 liters per minute, or as a result of airing the water supply system after it is turned off.

In such a situation, after starting the system in which air is present, during the intake of water by the washing machine, there is a sharp acceleration of the mixture of water and air passing through the valve. This "shot" of air and water is likely to trigger the valve.

And bringing the valve into working condition requires its complete removal, which can be very inconvenient with frequent false alarms.

It is clear that this device has the right to life, but its work requires compliance with a number of conditions, and life stubbornly speaks of its own, for example, that external factors are often beyond the control of the homeowner himself, whether it is low pressure in the water supply network or airing the system may cause false alarms or malfunction of such a device.

The ability of the device to work when the hose is completely broken is beyond praise, and the passivity to small but long-term leaks may call into question its advisability for use in home networks.

Those who do not abandon the search for devices to protect against water leaks can be advised to consider automatic shut-off devices installed in the water unit of the room, which are triggered by a signal from sensors that can be installed anywhere.

On this, let me finish, I wish that the plumbing does not let you down, good luck to everyone and see you soon.

Watch a detailed video about the operation of the Aquastop valve on the channel

|

|

| © tour-planet.com 2017 - 2025 |

Copying of texts, photos and other information for re-publication on other resources is allowed only with the written permission of the site administration. |